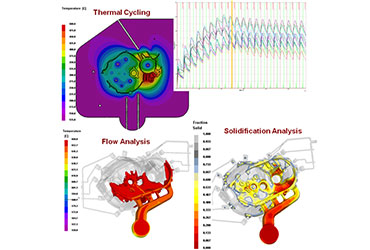

FEM based simulation software from ProCAST for Flow Analysis and Solidification Analysis for optimizing Design of Runners and Gates and Cooling Lines of the Die Casting Dies. The software facilitates prediction of Casting defects through Simulation results so as to optimize the casting process to improve the yield.

Two Platen Technology facilitates automatic strain Gauging and setting on individual Tie Bars.

• State-of-the-art SQUEEZE technology from Buhler switzerland deployed on cylider blocks.

• Auto Dozing : Metering exact quantity of molten metal and pouring into the shot sleeve.

• Closed Loop Controls : The set parameters of Die Casting are compared with actual shot parameters on continuous basis.

• Robotic Extraction : Combination Grippers are employed for placing Inserts, Liners in the die and extraction of hot castings from the die.

• Auto Sprayer : Dedicated Spray Heads for spraying metered quantities of Die Coat and compressed air on the set and intricate locations on the die.

Hitech trim tools are employed for degating and deflashing the hot castings on line by placing and removing the castings from the trim press which is interfaced with Die Casting Machine.

Fondarex Switzerland make Vacuum Die Casting Equipment is used to suck air from the die before taking a shot to avoid air entrapment in the casting so as to produce sound casting without porosity.

FLIR USA make Thermal Imaging Camera is used to take a thermal Image of the die to assess the temperature on the die surface. These pictures are used to set the auto spraying unit to achieve uniform temperature on the die surface.

Thermobiehl, Germany make Micro-processor controlled Heating Cooling Units are employed for soft heating, cooling of Die Casting Dies for maintaining thermal stability.

Ahresty, Japan make Micro-processor controlled Jet Cooling Equipment is used to cool the core pins so as to reduce the soldering on the core pins and reduce shrinkage porosity in the core holes.

Marposs,Italy make Autogauging Equipments are used for precise measurement of multiple dimensions on the machines castings at a time after machining.

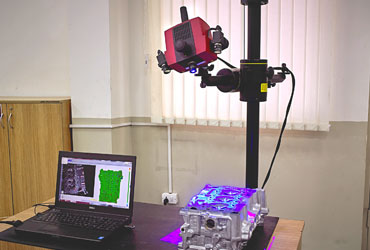

ATOS, Germany make GOM Equipment is used to scan the casting, die surface. Scanned data is then compared with CAD Model to assess the variance.